In the field of industrial automation, the importance of lifting motors is self-evident. These motors play a key role in a variety of applications, ranging from manufacturing and logistics to construction. Their ability to lift and move heavy objects with ease has revolutionized industrial operations, improving efficiency, safety and productivity.

Traditionally, lifting heavy objects is a labor-intensive task fraught with risk. However, with the advent of lifting motors, technology powered by electric, hydraulic or pneumatic systems, the process has changed dramatically. These motors provide precise control and maneuverability, making lifting, positioning and transporting heavy items precise and safe.

In addition, the integration of smart features, such as sensors and programmable controls, further enhances the capabilities of the hoist motor. This combination of technologies not only increases the speed and accuracy of lifting operations, but also minimizes human intervention, reducing the possibility of accidents and errors.

For example, in manufacturing, lifting motors in automated warehousing systems can accurately lift and place goods at designated locations, thereby speeding up the warehousing process and reducing errors caused by human manipulation. On construction sites, the use of crane motors can easily transport construction materials, improve construction efficiency and reduce personnel's physical exertion.

Complementing the lifting motor are automation motors, which have become an indispensable component in modern industrial environments. These motors serve as the driving force of automation systems, providing power support for various automated processes such as conveyor belts, robot arms, and assembly lines. Their versatility and adaptability transform manufacturing and production, driving efficiencies through optimized operations and resource utilization.

There are many types of automation motors, including servo motors, stepper motors, and AC and DC motors, each customized for a specific application. Servo motors, for example, offer unparalleled precision and control capabilities, making them ideal for complex tasks that require high precision. Stepper motors excel in applications requiring precise position control, while AC and DC motors provide robustness and reliability in a variety of industrial environments.

The integration of automated motors allows industrial systems to increase throughput, reduce downtime, and enhance quality control. They enable the development of modern manufacturing processes by enabling continuous and repetitive tasks to be completed with consistent precision and accuracy.

For example, in the automotive manufacturing industry, automated assembly lines use automated motors to accurately assemble parts to ensure the quality and consistency of the vehicle. In the food processing industry, automated conveyor belts utilize these motors for product packaging and sorting, improving production efficiency and ensuring product quality.

3. Future trends and innovations in lifting and automation motors

With the continuous advancement of technology, the development direction of lifting and automation motors is destined to usher in more innovations. Industry 4.0 concepts including the Internet of Things (IoT) and artificial intelligence are being integrated into motor systems, opening an era of interconnection and intelligent automation.

Predictive maintenance brought about by sensors embedded inside motors in the Internet of Things (IoT) makes it possible to maintain motors in advance, minimize unexpected downtime, and optimize performance. Additionally, advances in machine learning algorithms allow motors to adjust and optimize operation based on real-time data, thereby increasing efficiency and saving energy.

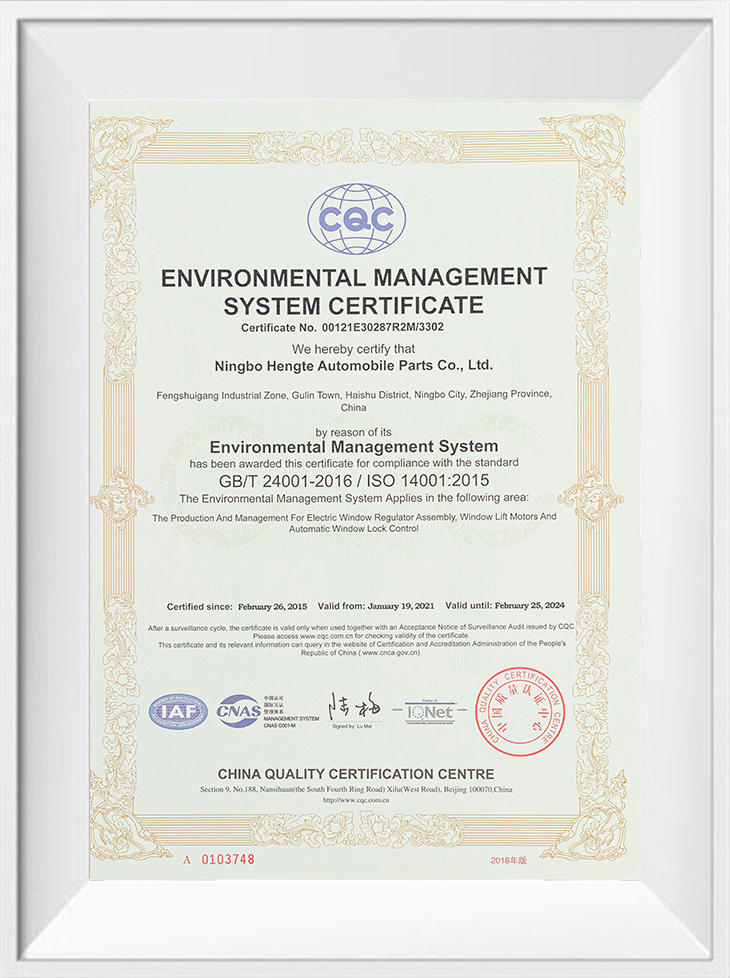

In addition, industry is increasingly paying attention to sustainability. Lifting and automation motor manufacturers are working to develop environmentally friendly solutions that reduce their carbon footprint by using energy-efficient designs and materials and adhering to strict environmental standards.

Developments in lifting and automation motors continue to redefine industrial processes, driving new heights of efficiency, precision and safety. As technological innovation continues, the integration of smart features and sustainable practices will shape the future of these motors, promoting a more connected, efficient and environmentally conscious industry.